Instant steam generator to power a GP system (Gillier Pantone): achievement advice

The "GP +" system is an evolution of water doping with a bubbler, called the GP system (in honor of its first experimenter, the farmer Antoine Gillet) by replacing the bulky bubbler by a steam generator.

The original idea comes from Michel Lathuraz, whose nickname is Camel1. The idea and design of the steam generator was developed largely on the forums which is an example of a Peugeot 205.

It is this assembly which was carried out at the Mayor of Vitry sur Orne.

To fully understand the interest of a steam generator, see the previous page: steam generator, principle and advantages

Schematic diagram

First, an exploded view of the annular SG. It is integrated into the exhaust line, after the reactor, as centered as possible with respect to the axis of the exhaust gases.

A freehand plan, which gives the dimensions concerning XUD7 the engine of 205. The dimensions must be adapted depending on the cylinder capacity and the type of engine (for calculation, see below).

sizing

The rise in temperature of the SG is proportional to its heat exchange surface.

If the engine displacement increases, the exhaust flow also increases (for a given speed and exhaust temperature), i.e. the flow of gases passing over the exchanger per unit of time is greater, thus releasing more calories, and resulting in a steeper temperature rise curve. So there is a simple rule of three to do, to get the dimensions.

Empirical formula to calculate these dimensions according to the displacement of a diesel engine with inner tubes of 16/18 mm and outer of 20 / 22mm.

a) For a diesel engine

L = 240 / C with L the tube length in mm C engine size in liters.

Examples: for a diesel engine 1.9L will require a length of 240 / 1,9 126 = mm.

b) For a gasoline engine

L = 240 / 1,25 192 = * C / C

For a petrol engine, a coefficient of 1,25 must be applied (ie divide the result by 1,25), because the exhaust gases are hotter.

Examples: for a gasoline engine 1.2L will require a length of 192 / 1,2 160 = mm.

This formula will probably subsequently improved, but allows a priori to fall for the usual displacements in the right temperature values and amount of the injected steam.

Manufacturing

Here is a view of the brass pieces prepared for this future GV. The inner tube is red hot at the ends, to be flared with a conical metal object of suitable dimensions, gently struck with a mallet. It is ensured that the flaring allows the tube to enter the outer tube, with a slight play, which will make it possible to easily achieve a nice closing solder.

Prior verification, it adjusts:

We solder the fittings, then we carefully file what protrudes inside the outer tube with a big "rat tail", all that remains is the soldering of the ends to be made:

Result:

And the mainsail placed in the exhaust line - here on Mercedes Didier, we make two holes in the exhaust tube, one towards the mouth, diameter 12,5mm, for the steam outlet, and the other towards the bottom of the mainsail, diameter 4,5mm, for the tube water supply. It is necessary to "work" this small hole with an old drill bit (or a piece of scrap of 4 mm) by tilting it towards the back (in the direction of the GE) to facilitate the entry of the feeding tube.

Before installing the mainsail, care will be taken to make an expansion loop of this tube, towards the mains water inlet, intended to absorb the expansion of the heated copper.

Once the two tubes have been passed, and the mainsail carefully centered in the exhaust, all that remains is to solder them, or better, to weld them with TIG.

Of course, for the installation, it will be necessary to imagine solutions on a case by case basis, given the diversity of the exhaust lines.

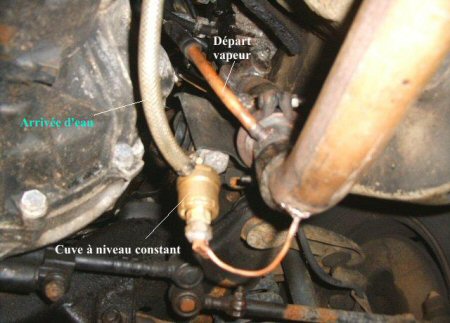

Finally, here is a view from below of the assembly resting on the car, which gives a good idea of the general arrangement of the elements. The constant level tank is positioned so that the bottom of the mainsail is flooded (about two cm) This photo is missing its fixing flange, which prevents it from moving and constraining the supply tube, as well as the tube balancing, which must connect the tank cover to the steam outlet of the mainsail by a hose of small diameter In fact, following the multiplication of mainsail achievements, and thanks to the feedback generated, it appears that There are cases where the depression conditions towards the outlet of the mainsail cause a more or less chaotic upwelling of water, well beyond the level of equilibrium obtained at rest.

The extremely simple solution consists in canceling the pressure difference between the constant level tank and the outlet of the SG. It is therefore necessary to replace the small vent hole, on the top of the tank, with a small diameter copper outlet, connected by a small diameter hose planted in the steam outlet hose. Thus, we have the guarantee of a stable level, whatever the engine on which it is adapted ...

To secure the water supply, and have precise control over the maximum water flow per hour, all you have to do is, as Yoan suggested to me, a supply by flexible pipe fitted with a flowmeter. "Drip" type hospital infusion.