Salutations to all .

I search for info, see plans, to create a methanizer famillial.

Between the peelings, garden waste and the product of our TLB (biomedridden litter toilet) we produce a nice little pile of manure at 4.

We know the methanizers built and used by breeders.

are there any feedbacks on small models?

-Quantity of material for quantity of gas.

-Volume methanizer and tank.

-Risks (H²S) and possible problems

At your service

properly

Philippe

Self-construction of a "family" methaniser

Self-construction of a "family" methaniser

0 x

As said the one who jumped

from the 20th floor passing in front of the 10th ... "until then, it's okay"

from the 20th floor passing in front of the 10th ... "until then, it's okay"

-

Christophe

- Moderator

- posts: 79289

- Registration: 10/02/03, 14:06

- Location: Greenhouse planet

- x 11025

Hi and welcome.

Several quick answers:

a) methanogenic potential: with household waste, even cutting garden is weak and not hope to do more than cooking (or complement) in our latitudes.

Here are the different methanogenic powers (ideal conditions): https://www.econologie.com/forums/biogaz-met ... t2338.html

Also do a search

I quote the essential:

b) I think the most affordable method is the "jean pain" method, here are some explanations: https://www.econologie.com/forums/micro-proj ... vt898.html

To my knowledge no econologist has ever really tested "in real" at home so I do not know what it's worth ...

Several quick answers:

a) methanogenic potential: with household waste, even cutting garden is weak and not hope to do more than cooking (or complement) in our latitudes.

Here are the different methanogenic powers (ideal conditions): https://www.econologie.com/forums/biogaz-met ... t2338.html

Also do a search

I quote the essential:

it is necessary, according to the material, between 10 and 20Kg of material to make the equivalent of one L of fuel under optimum conditions of yield (bacteriology and ideal conditions of T °, agitation, ph ... etc).

b) I think the most affordable method is the "jean pain" method, here are some explanations: https://www.econologie.com/forums/micro-proj ... vt898.html

To my knowledge no econologist has ever really tested "in real" at home so I do not know what it's worth ...

The man who draws energy from the scrub

It was almost dark when I arrived at the Templar estate, a forest area of 240 hectares leaning against the Alpes de Haute Provence. At the bend of a bumpy dirt track that winds through a meager scrubland near Villecroze, in the Var, I discovered the large white house of Jean Pain.

Ten years ago, at the age of forty-one, this little industrialist from Grenoble decided to give up everything to become a ranger without pay, even if he had to feed his wife and son with difficulty on 3 acres of mediocre land. Today, he is hailed as "the pope of green gold". From all continents, energy specialists have come to the Templar estate to study the miracle he has accomplished: a simple and economical way to produce energy and fertilizer from the undergrowth. An original system in which these scientists see a strong hope, a significant response to the global problem posed by the shortage of fuels.

International expert on energy, Robert Giry, author of Le Nucléaire inutile? (Editions Entente), wrote: "In this time of crisis where we will suddenly find ourselves suddenly deprived of energy, the path traced by Jean Pain for the production of fertilizer, fuel and electricity is a solution full of future. "

A magic "cake" As a wrestler and serenity hermit, the master of the place greets me on the doorstep with his wife Ida. Immediately he leads me to about fifty meters away to show me the object that causes so much curiosity, this "central" he designed and that provides his family the energy it needs. What I see is a huge "cylindrical cake" 3 meters high 6 diameter, weighing 50 tons, made of small brush debris: heather, juniper, fern, broom, thyme, pine, etc.

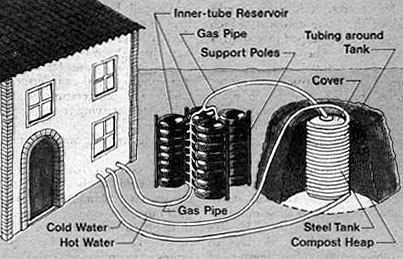

This vegetable cocktail, explains Jean Pain, is a compost composed only of ligneous materials (green branches in leaves or buds) and crushed brushwood, comparable to piles of decomposing organic matter (leaves and food residues) that many people maintain in their garden. Buried in the middle of the compost, there is an airtight steel tank of 4 cubic meters three quarters full of these same debris of two months of age, macerating in the water. Heated itself by the fermentation of the compost that surrounds it, this tank produces methane that will be stored nearby in truck inner tubes connected to the tank by a pipe.

"Once washed by a passage on wet pebbles, then compressed, says the inventor, this gas is used to cook our food and to manufacture our electricity; it also provides fuel for our vehicles. "It takes ninety days at the facility to produce the 500 cubic meters of gas that feed both stoves and Ida's three-burner stove. Behind the house, in a special room, Jean Pain shows me a gasoline engine, running on methane, that runs a generator generating 100 kilowatts per hour. The family does not need anything else to light their house. When Ida starts driving her Citroen van, I notice on the roof two gas cylinders in the form of shells, containing 5 cubic meters of gas and allowing a range of 100 kilometers. "Ten kilograms of scrub," her husband tells me, "provide the equivalent of a liter of super gas: it was enough to modify the carburetor slightly"!

Returning to the compost, Jean shows me a plastic tube of 40 millimeters in diameter that comes out of a well, passes through the "cake" of debris and ends in a tap in the house. He explained to me that in the center of the installation the fermentation of the compost raises the temperature, so that the cold water coming from the well, after having crossed 200 meters in the serpentine pipe around the steel tank , spring at 60 degrees. I check that entering the water is cold and hot on exit. This hot water, circulating in radiators, is used to heat the house.

A heap of compost, the size of the one I see can deliver hot water for nearly eighteen months at a rate of 4 liters per minute, enough to power the central heating, bathroom and kitchen. Then the installation will be dismantled, the pipe will be recovered to serve a new operation that will be put in place immediately to ensure continuity, and the compost will be returned to the ground.

Legend:

Cold Water: cold water

Hot Water: hot water

Inner-tube Reservoir: tires

Gas Pipe: gas pipe

Support Poles: Poles of maintains

Tubing around Tank: piping around the tank

Cover: lid

Steel Tank: steel tank

Compost Heap: compost pile

Fifteen years of effort. Because this heap of brush reduced in lint still has another use. Once fermentation is complete, this magic cake stops producing energy, but it then provides 50 tons of natural and balanced fertilizer. By spreading a thick layer of this humus on the stony ground that surrounds his home, Jean Pain has created a sumptuous vegetable garden where grow up to tropical vegetables. I admire tomato plants of 2,50 m high, a watermelon of 6 kilos; there are even some christophines, a sort of sweet squash, usually found only in the West Indies and in Black Africa. What surprises me most is that all these giant products are obtained without watering: it is in compost, Jean Pain tells me, that the synthesis of the water they need is done.

The ingenious power plant that he developed and built with his own hands cost him fifteen years of unremitting efforts. In picking up brushwood, he had not failed to notice that wherever it was found, the vegetation seemed more vigorous; not surprising: by breaking down, branches, leaves and bushes form humus. It is said that, to imitate nature, it was possible to remove the excess undergrowth in the forests, and perhaps also to domesticate the energy produced by the fermentation which transforms these scrubs into humus. As André Birre, author of The Humus, Wealth and Health of the Earth (edition The Rustic House) says: "One hypnotizes oneself on the black gold of the oil, with the limited deposits, without seeing that everybody can do to fructify without exhaustion, by increasing it even continuously, this other gold, that of the humus >>

Devoid of any degree but endowed with a keen intelligence as well as exceptional faculties of adaptation and observation, Jean Pain, from 1965, devours dozens of scientific books while realizing his first experiences. He begins by fermenting the scrub as he cut it in the undergrowth, but he soon realizes that for branches with a larger diameter it is necessary to chop the debris as finely as possible. As there is no machine adapted to this work, he imagines one and builds it in his garage, using recycled materials.

Providence forest. The impact of this discovery is immense. For Jean Pain, the forest can become the providence of the man of the nineteenth century. The challenge is obviously important for France. While it imports 21 millions tons of oil every year, which seriously unbalances its balance of trade, the French forest represents an energy supplement whose biologist Robert du Pontavice figures the potential to 126 millions of tons of oil equivalent (PET) . And it is not about unworkable theoretical resources; Jean Pain does not elude the question of profitability. He has done and redid his calculations, and the numbers are there: 20 hectares of forest can provide each year 1000 6 tons of fertilizer, 000 960 cubic meters of biogas and millions of liters of hot water. But to exploit the forest we spend only 000%, energy that we collect. And the cycle is repeated indefinitely, since the scrub is renewed every seven years. The idea is doubly interesting: on the one hand, the forest is clean and safe from the fire, on the other an inexhaustible reservoir of fertilizer and thermal energy.

In France as abroad, many already are those who implement the techniques developed by the inventor. Eight municipalities, including Draguignan (Var), Nice (Alpes-Maritimes), Lutter bach (Haut-Rhin), Caen (Calvados), Commensacq (Landes), have chosen to adopt its method of recycling vegetation to produce heat and hot water for public buildings, buildings, greenhouses or sports facilities. "In Saintpuits, in the Yonne, village of 500 inhabitants, we heat several residential buildings in order to demonstrate the value of the process," affirms Étienne Bonvallet, prime contractor for this pilot operation.

The municipality of Chambéry (Savoie) uses the method of Jean Pain since January 1980. A 200 cubic meter compost wheel, formed of crushed branches from the pruning of the plane trees and lime trees of the city, provides 23 400 calories per hour and provides heating of a greenhouse of 200 square meters. After two years, it will be possible to recover 80 cubic meters of potting soil for municipal gardens.

In the heart of the Landes de Gasgogne, in Pontenx-les-Forges, an interesting experience has been realized since the beginning of 1980 by the Association intercommunale du Born, which groups together 14 communes. A team of volunteer ecologists is collecting 20 cubic meters of branches, shrubs and bark from pine pruning. Shredded by a Jean Pain crusher, these debris will constitute two millstones supplemented with 50%, by household rubbish pulverized. After fermentation, the product will be sold as fertilizer to horticulturists, farmers and garden owners in the region.

As Henri Stehlé, a world-renowned agronomist and botanist, laureate of the Institut de France, says: "At the end of the path drawn by Jean Pain, there is the agricultural enterprise of tomorrow, autonomous, producing itself what to fertilize its soil and operate its equipment >>

In Belgium and elsewhere. The methods of extracting green gold are beginning to spread in Europe. At Londerzeel, 20 kilometers north of Brussels, a composting yard is flanked by a flourishing garden. It is the center of experimentation of the Jean Pain International Committee (18, avenue Princesse Élisabeth, 1030 Brussels, Belgium), created in 1978 by Mr. Frederik Vanden Brande, its president, former Belgian secretary general of the Council of European Municipalities .

On the site, it is a constant back and forth of trucks and tractors spilling their load of brush. Three compost wheels (150 tons in total) feed the garden with fertilizer; there is an orchard, a nursery of trees, flowers and medicinal plants, and an experimental section for wheat. Yields are 15%, above average. As the center is not a commercial enterprise, the harvests are distributed free to families of the commune.

Thin, the white wick in battle, dressed in velvet and boots, Frederik Vanden Brande responsible for the team of four workers made available by the government, explains: "In 1979, we launched a first call to 17 000 inhabitants of Londerzeel to collect scrub and pruning or pruning wood; in a fortnight they brought us 280 cubic meters of plants. In one year, our compost production has gone from 25 to 275 cubic meters. "

On the strength of this success, the Belgian Committee launched, in January 1980, a national campaign for the collection of brushwood: 200 common on the 600 that includes the kingdom take part in the operation.

The center of Londerzeel is today the showcase and the pride of the Jean Pain Committee, but this one has many other activities. It publishes leaflets, gives conferences, organizes monthly open days and, twice a year, fifteen-day courses where a hundred farmers, students and ecologists come from a wide variety of backgrounds. introduce methods of grinding, composting and methane production. In April 1980, the Belgian Ministry of Foreign Affairs and Cooperation entrusted the Committee with the organization of a seminar that brought together 32 agronomists, mostly from Africa.

All over the world, Jean Pain's methods are opening up an immense field of application to them. The inventor has fervent followers in the United States, Australia, Tunisia, Latin America, and Japan. The book he wrote with his wife, translated into five languages, has sold 70 000 copies.

0 x

Do a image search or an text search - Netiquette of forum

Thank you Christophe

All this, I had already read it.

I'm looking for technical and practical details to do something serious and clean.

I found some videos but the explanations are often missing as here:

Indeed, as far as I am concerned, this would only serve to fuel the gas cooker.

Anyway, I will test and keep you informed.

Philippe

All this, I had already read it.

I'm looking for technical and practical details to do something serious and clean.

I found some videos but the explanations are often missing as here:

Indeed, as far as I am concerned, this would only serve to fuel the gas cooker.

Anyway, I will test and keep you informed.

Philippe

0 x

As said the one who jumped

from the 20th floor passing in front of the 10th ... "until then, it's okay"

from the 20th floor passing in front of the 10th ... "until then, it's okay"

-

Christophe

- Moderator

- posts: 79289

- Registration: 10/02/03, 14:06

- Location: Greenhouse planet

- x 11025

Well with the association we have as a project, among others, to develop a "biogas barbecue" ...

To see if it's really realistic ... considering the investment, reliability, efficiency ...

In any case the 2 ideas come together! Nice videos!

To see if it's really realistic ... considering the investment, reliability, efficiency ...

In any case the 2 ideas come together! Nice videos!

0 x

Do a image search or an text search - Netiquette of forum

methane

Subsidiary question

In a classic septic tank there is decomposing matter and water. Does it release methane?

There is a ventilation pipe in any case ...

Can it be missing from the plant material ...

If anyone knows the topic Thank you

In a classic septic tank there is decomposing matter and water. Does it release methane?

There is a ventilation pipe in any case ...

Can it be missing from the plant material ...

If anyone knows the topic Thank you

0 x

As said the one who jumped

from the 20th floor passing in front of the 10th ... "until then, it's okay"

from the 20th floor passing in front of the 10th ... "until then, it's okay"

- chatelot16

- Econologue expert

- posts: 6960

- Registration: 11/11/07, 17:33

- Location: Angouleme

- x 264

to make methane there is absolutely no need of oxygen: with oxygen the bacteria finish their work of destruction until CO2

for a septic tank to make methane it would be necessary to avoid diluting the can of shit that one puts there by enormous volume of clean water full of dissolved oxygen: when I will have a méthanisation which works I will seek a means Feed flushes with recycled water low in oxygen ...

with the dry toilet is not better: it should be sheltered from the air immediately, otherwise it makes compost not methanization

that is why methanisation works much better in countries where less water is wasted than at home

human excrement is not very rich for methanization: green trash lawn or hedge trimmers are more interesting, but not alone, excrement and manure are useful adjuncts

remains to find a way that works: cold, soil temperature, the methanization is very slow, it would take a huge tank for not much

for a resonable methanization rate it is necessary to heat to 37 or 40 °, it is less simple

it requires a constant temperature, not a DIY that is heated from time to time: it pushes to make it bigger than for its own waste: centralize the green waste of an entire village ...

for a septic tank to make methane it would be necessary to avoid diluting the can of shit that one puts there by enormous volume of clean water full of dissolved oxygen: when I will have a méthanisation which works I will seek a means Feed flushes with recycled water low in oxygen ...

with the dry toilet is not better: it should be sheltered from the air immediately, otherwise it makes compost not methanization

that is why methanisation works much better in countries where less water is wasted than at home

human excrement is not very rich for methanization: green trash lawn or hedge trimmers are more interesting, but not alone, excrement and manure are useful adjuncts

remains to find a way that works: cold, soil temperature, the methanization is very slow, it would take a huge tank for not much

for a resonable methanization rate it is necessary to heat to 37 or 40 °, it is less simple

it requires a constant temperature, not a DIY that is heated from time to time: it pushes to make it bigger than for its own waste: centralize the green waste of an entire village ...

0 x

methanisation

Thank you Chatelot for these interresting news.

I nevertheless found this

: http://www.onpeutlefaire.com/produire-son-propre-biogaz

And even if it is not really usable, I want to try "for fun"

If it fuels a gas barbeuk, it's already that ... to show that there are solutions ....

A +

properly

Philippe

I nevertheless found this

: http://www.onpeutlefaire.com/produire-son-propre-biogaz

And even if it is not really usable, I want to try "for fun"

If it fuels a gas barbeuk, it's already that ... to show that there are solutions ....

A +

properly

Philippe

0 x

As said the one who jumped

from the 20th floor passing in front of the 10th ... "until then, it's okay"

from the 20th floor passing in front of the 10th ... "until then, it's okay"

- chatelot16

- Econologue expert

- posts: 6960

- Registration: 11/11/07, 17:33

- Location: Angouleme

- x 264

biometane for barbeuk? yuck !!!

biomethane is dirty methane: to burn completely

the butane barbeuk is already a little doubtful: the fat that falls on the stones burns badly is made anything that polishes what we eat

the real charcoal barbecue is much cleaner: not only is charcoal a clean fuel, but it absorbs the fat that falls on it and helps it to burn cleanly

I'm a real fan of methanisation as a way to do more energy, but not for the barbecue

the simplistic trick of it can be done, is the best way to show that it does not work: damage since with the good way it works ...

the methanisation is slow: if you want to make a demonstration for a barbeuk or to cook on a gas stove you must have accumulated enough gas! the air chamber hanged anyhow is not worth much: the good solution is the gasometer: a bell made of sheet metal or plastic hanging over a tank or basin of water, and balanced by one or counterweights and pulley: the gasometer gives a very constant pressure: the methanisation produces gas the time it takes: when the gasometer is full we are sure to cook something completely

biomethane is dirty methane: to burn completely

the butane barbeuk is already a little doubtful: the fat that falls on the stones burns badly is made anything that polishes what we eat

the real charcoal barbecue is much cleaner: not only is charcoal a clean fuel, but it absorbs the fat that falls on it and helps it to burn cleanly

I'm a real fan of methanisation as a way to do more energy, but not for the barbecue

the simplistic trick of it can be done, is the best way to show that it does not work: damage since with the good way it works ...

the methanisation is slow: if you want to make a demonstration for a barbeuk or to cook on a gas stove you must have accumulated enough gas! the air chamber hanged anyhow is not worth much: the good solution is the gasometer: a bell made of sheet metal or plastic hanging over a tank or basin of water, and balanced by one or counterweights and pulley: the gasometer gives a very constant pressure: the methanisation produces gas the time it takes: when the gasometer is full we are sure to cook something completely

0 x

Re: Self-construction of a "family" methaniser

Hello everyone,

I unearth this post to avoid creating another one.

my project is pretty much the same: to supply gas to a stove for my summer kitchen.

after my first research, since the temperature should be about 37 ° in the tank, I think to make a simple assembly that will only produce the summer (late May to late September). using grass clippings and kitchen waste (what about meat?)

I think to store gas in truck inner tubes. the digestate will be used to enrich the garden in the fall

if the test is successful, it will be possible to create a more efficient set (with integrated heating) and fill bottles because I have a compressor (10 bar max).

what performance can I expect with the first assembly? an inner tube will produce a flame how long?

thank you for your lighting complements

my assembly will be done on this principle:

I unearth this post to avoid creating another one.

my project is pretty much the same: to supply gas to a stove for my summer kitchen.

after my first research, since the temperature should be about 37 ° in the tank, I think to make a simple assembly that will only produce the summer (late May to late September). using grass clippings and kitchen waste (what about meat?)

I think to store gas in truck inner tubes. the digestate will be used to enrich the garden in the fall

if the test is successful, it will be possible to create a more efficient set (with integrated heating) and fill bottles because I have a compressor (10 bar max).

what performance can I expect with the first assembly? an inner tube will produce a flame how long?

thank you for your lighting complements

my assembly will be done on this principle:

0 x

Re: Self-construction of a "family" methaniser

Hello,

I am new to the forum and I'm interested in methanisation too. Living in an apartment I have not had the opportunity to experiment, however I found some sites that can help research:

http://www.bio-e-co.fr/biogaz,traitemen ... tonome.php

http://en.puxintech.com/puxinseptic

They are two manufacturers of "methaniser septic tanks" the first is French, the second Chinese I believe.

Jean-Philipe Valla, a market gardener built himself a “biogas: practical manual” tank and very interesting it can be found in pdf: https://www.latelierpaysan.org/IMG/pdf/ ... erme-2.pdf

As well as his conference "100% energy autonomous on the farm" where he talks about anaerobic digestion and many other very interesting topics:

In terms of self-construction bio-e-co offers a kit where they rent molds to fill with concrete. All this is big installation, for smaller and periodic I remember that some videos on YouTube of people who made digesters in cans.

Hoping to have helped someone, good luck and share your advancements.

I am new to the forum and I'm interested in methanisation too. Living in an apartment I have not had the opportunity to experiment, however I found some sites that can help research:

http://www.bio-e-co.fr/biogaz,traitemen ... tonome.php

http://en.puxintech.com/puxinseptic

They are two manufacturers of "methaniser septic tanks" the first is French, the second Chinese I believe.

Jean-Philipe Valla, a market gardener built himself a “biogas: practical manual” tank and very interesting it can be found in pdf: https://www.latelierpaysan.org/IMG/pdf/ ... erme-2.pdf

As well as his conference "100% energy autonomous on the farm" where he talks about anaerobic digestion and many other very interesting topics:

In terms of self-construction bio-e-co offers a kit where they rent molds to fill with concrete. All this is big installation, for smaller and periodic I remember that some videos on YouTube of people who made digesters in cans.

Hoping to have helped someone, good luck and share your advancements.

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 4 Replies

- 1946 views

-

Last message by Remundo

View the latest post

29/01/23, 19:06A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 2 Replies

- 7428 views

-

Last message by BaudouinLabrique

View the latest post

17/05/23, 14:56A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 1 Replies

- 3234 views

-

Last message by izentrop

View the latest post

30/06/18, 07:00A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 7 Replies

- 9009 views

-

Last message by dellastrada

View the latest post

01/07/18, 20:42A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 1 Replies

- 3680 views

-

Last message by yves35

View the latest post

03/10/16, 01:53A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

Back to "hydraulic, wind, geothermal, marine energy, biogas ..."

Who is online ?

Users browsing this forum : No registered users and 161 guests