Hello Denis

Yes a benefit, but the design requires more work and more welding, the clutter following the place under the hood

not to make too many restrictions on the exhaust the second

pass must be wider ..

Andre

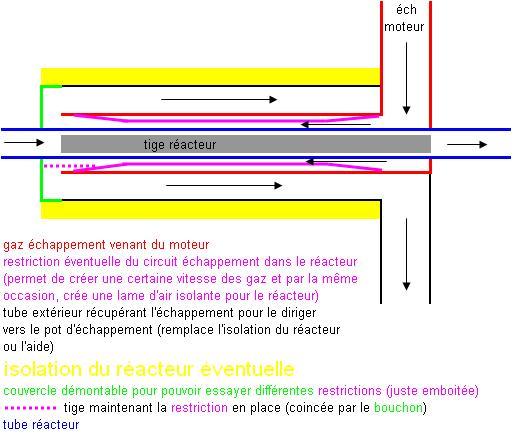

Pantone assembly for experiments and measurements

Andre wrote:Hello Denis

Yes a benefit, but the design requires more work and more welding, the clutter following the place under the hood

not to make too many restrictions on the exhaust the second

pass must be wider ..

Andre

Good evening

Exactly: Do not make restrictions where there is no benefit to the system (unnecessary losses)

the restriction makes it possible to increase the speed of the gases (ie if this really brings something positive (for ionization or "cracking")) while creating an insulating air gap for the reactor

the interest to make it removable is precisely to be able to try different spaces of restriction (only by changing the tube in pink) and this is easier by turning the exhaust gas on the same side as the arrival kind toyota hillux Lau

I was only asking the question: does the fact of making the flow go outside in the same direction as the gas geet, is not harmful to its production

in the wild, I've heard that for it to work well, do not be afraid to make the exhaust restriction against the reactor (passage between the pink tube and the blue) and that it does not do too much wrong given the revival brought by the gas geet

rod (gray) / reactor tube (blue): space 1 mm

reactor tube (blue) / gas tube (pink): space only 2 mm

on a turbo engine, it has to brake a bit hard

me, the only thing I noticed is that the rod becomes much faster brown (with its insulating layer), with a strong restriction: less than half an hour (motor at full load)

that would mean that it rode much faster with either a high speed of the gases ech (space of 2 mm between a diameter of 21 mm (ext reactor) and 25 mm (int tube ech at this place)

on an 100 ch accelerated and fully loaded tractor, it must go well beyond the sound barrier

a greater concentration of heat on the reactor

bolt

0 x

Hello

I always advocate but it is long discussions motorists specialists, it also goes against everything we have been taught.

it's a little in this style that I did my editing on the Mercedes, with a significant restriction and that behind the turbo without knowing the risks for the trubo!

it is not necessary to be stretched all along the reactor, just on the part before the first 1 / 4 then flare this deflector, 7 degrees actually make a venturi it is this form that gives the least restriction , with such a mounting stainless steel deflector the return of the exhaust gas becomes less necessary, part of the heat crosses the baffle and then there is the body of the exhaust pipe, (The heat always goes to the place where it can exchange, the end of the reactor). we end up with the principle of double-bottomed pans and in addition a layer of air between.

This principle, which can be used by many manufacturers to make the flexible grids of the exhausts less heat-resistant, uses a thin tube of stainless steel to cut the heat of the anti-vibration bellows.

when to counter sense for thermal reasons yes, but for other reasons I emit reseves ..

Andre

in the wild, I've heard that for it to work well, do not be afraid to make the exhaust restriction against the reactor (passage between the pink tube and the blue) and that it does not do too much wrong given the revival brought by the gas geet

I always advocate but it is long discussions motorists specialists, it also goes against everything we have been taught.

it's a little in this style that I did my editing on the Mercedes, with a significant restriction and that behind the turbo without knowing the risks for the trubo!

it is not necessary to be stretched all along the reactor, just on the part before the first 1 / 4 then flare this deflector, 7 degrees actually make a venturi it is this form that gives the least restriction , with such a mounting stainless steel deflector the return of the exhaust gas becomes less necessary, part of the heat crosses the baffle and then there is the body of the exhaust pipe, (The heat always goes to the place where it can exchange, the end of the reactor). we end up with the principle of double-bottomed pans and in addition a layer of air between.

This principle, which can be used by many manufacturers to make the flexible grids of the exhausts less heat-resistant, uses a thin tube of stainless steel to cut the heat of the anti-vibration bellows.

when to counter sense for thermal reasons yes, but for other reasons I emit reseves ..

Andre

0 x

Andre wrote:I always advocate but it is long discussions motorists specialists, it also goes against everything we have been taught.

it's a little in this style that I did my editing on the Mercedes, with a significant restriction and that behind the turbo without knowing the risks for the trubo!

For "long discussions", that does not surprise me.

André, have you already measured the residual pressure output ech engine (after the turbo, since you are equipped) and before your restriction of the reactor

Me, I tried like the diagram above:

with a restriction of 4 cm length and 2,5 mm env space, I have 0,45 bar in the pipe ech (before the reactor)

with a restriction of 15 cm length but 3,5 mm space approx, I have 0,55 bar (at full speed, because at idle, it spends much less volume, and the pressure falls unless 0,1 bar in the 2 case)

With a restriction, it seems logical that at high speed the engine is disturbed in its maximum power, (but since the restriction will be the cinéquanone condition for the reactor to work, we must juggle this compromise)

and therefore, the pantone is more efficient at the average speed

It should also be noted that the restriction, which certainly tends to reduce the amount of air swallowed by the engine, necessarily implies (for the same amount of diesel) a higher T ° at the same time (for the same application load)

so it's a bit like putting a smaller engine on the same vehicle

and as we know that on a motor insufficiently loaded, the pantone works less well

the fact of making swallow less air to the engine, because of this restriction, there is less air to heat

the engine, let us admit too powerful of origin for such a vehicle, capable of driving at more than 180 km / h, is virtually "in full load" at 90 km / h: maximum heat at the scale, while being qu '' at a quarter of the full load diesel flow

morality:

on a tractor that always works near the maximum power, heat is available without much restriction

but on an overpowered car which does not run for long at all under full load, do not be afraid to make a good restriction (here, I am speaking to make the pantone work, knowing of course, that in the case of '' a very strong restriction, it will undoubtedly be necessary to limit the full load flow of the injection pump so as not to smoke black at high speed and pedal to the floor, or to go very soft on the mushroom, but if the pantone works, the "very soft" will suffice)

it is for this reason that it is interesting to be able to modify this restriction easily, and to see how far it can be reduced, and so from this reduction, the consumption of the vehicle is no longer diminished.

bolt

0 x

Hello

I did not measure the exhaust pressure, it would have had to measure it before I made this restriction, in my case the restriction is more in the 50% of the exhaust duct, and even sometimes I test a hard restriction l, admission in the same order 50% more especially when I ride the city,

On the Mercedes 300 TD it never smokes, even if I completely stop the intake it pulls all through the reactor and I put full throttle the engine takes no turns and no fummé, there is a sytéme that takes the pressure in the intake manifold and which controls the injection pump it delivers diesel only if the air is available .. if the fuel filter clogs, it's the same thing we can not reach the top speed, the speeds automatic take a lot of time to change it stays longer on the intermediate reports that does it with the march to oil peanut even heated 70c ..

The restriction the only problem that it happened to me if I roll to the floor the engine temperature increases the radiator no longer supplied, running the oil exhaust and the reactor becomes hotter than with diesel, I managed to have a reactor outlet 270c, rolling the mat, never with diesel I catch 220c.

Now that the temperatures are going down, it will become more difficult to have good tests .. 5c this morning and 12c in the afternoon

Why such a big differrence with an 25c? the panton does not like the cool, I come from a test run in the eastern cantons, 504 km that took 41 liters of peanuts and 7,7 liters of water, it is slightly better than the diesel without panton (9 liters 100km without panton) but it becomes demanding to measure the oil in a calibrated recipian in a parking area, where the truckers look at you fill the small tank of 20 liters has boats in the trunk, with the frying and you must not escape .. all 230km you have to think about it,

it will have to improve the sytéme .. it's free but not practical ..

Host Image with PicTiger

Andre

I did not measure the exhaust pressure, it would have had to measure it before I made this restriction, in my case the restriction is more in the 50% of the exhaust duct, and even sometimes I test a hard restriction l, admission in the same order 50% more especially when I ride the city,

On the Mercedes 300 TD it never smokes, even if I completely stop the intake it pulls all through the reactor and I put full throttle the engine takes no turns and no fummé, there is a sytéme that takes the pressure in the intake manifold and which controls the injection pump it delivers diesel only if the air is available .. if the fuel filter clogs, it's the same thing we can not reach the top speed, the speeds automatic take a lot of time to change it stays longer on the intermediate reports that does it with the march to oil peanut even heated 70c ..

The restriction the only problem that it happened to me if I roll to the floor the engine temperature increases the radiator no longer supplied, running the oil exhaust and the reactor becomes hotter than with diesel, I managed to have a reactor outlet 270c, rolling the mat, never with diesel I catch 220c.

Now that the temperatures are going down, it will become more difficult to have good tests .. 5c this morning and 12c in the afternoon

Why such a big differrence with an 25c? the panton does not like the cool, I come from a test run in the eastern cantons, 504 km that took 41 liters of peanuts and 7,7 liters of water, it is slightly better than the diesel without panton (9 liters 100km without panton) but it becomes demanding to measure the oil in a calibrated recipian in a parking area, where the truckers look at you fill the small tank of 20 liters has boats in the trunk, with the frying and you must not escape .. all 230km you have to think about it,

it will have to improve the sytéme .. it's free but not practical ..

Host Image with PicTiger

Andre

0 x

Andre wrote:I did not measure the exhaust pressure, it would have had to measure it before I made this restriction, in my case the restriction is more in the 50% of the exhaust duct, and even sometimes I test a hard restriction l, admission in the same order 50% more especially when I ride the city,

Hello André

50% of the original section (if it has the same shape) multiplies the pressure drop by env 5, but if it is a short length, and that original loss is insignificant: multiplied by 5 can remain insignificant

eg a pipe of diameter 50 mm on 15 cm long, 400 m3 / h gas ech gives a loss of only 0,7 mbar, ie 0,0007 bar

X 5 = 0,0035 bar, ie 3,5 cm water column

if it's 50% of diameter it is X 34, either 0,0238 bar, or 23,8 cm water column, and if it is only restricted to a length of 5 cm, it is 3 times less

even if it is never good to brake the echo, it is still ridiculous for an engine atm, for a turbo engine, the influence is undoubtedly more marked

that's why I'd like you to measure your actual pressure drop, to get a clear idea of the restriction

Andre wrote:On the Mercedes 300 TD it never smokes, even if I completely stop the intake it pulls all through the reactor and I put full throttle the engine takes no turns and no fummé, there is a sytéme that takes the pressure in the intake manifold and which controls the injection pump it delivers diesel only if the air is available ..

with this system of regulation of the diesel flow, you could try all the restrictions that you want without polluting

Another discussion: the turbos were put on the engines to be able to decrease the engine capacity without losing power, and at the same time, it had to allow to consume less, since a smaller engine is less hard to turn (the horses with dung are fewer

the turbo increases as the call for power, the volume of air sucked by the engine, is equivalent in some way to adapt the engine displacement to the requested power

so that virtually the engine is much more often as if it was fully loaded (compared to an engine of the same power with a larger engine capacity)

and as we know that the closer to the full load, the better the specific consumption

but here, as the turbo brakes the exhaust gas, it can be assumed that it also brakes the trigger during the engine time, and we can assume that the same relaxation without being braked could be generated with a little less diesel injected

so on a pantone, the restriction is going consume necessarily more, if it does not produce the beneficial endothermic reaction on combustion in part cons

if there was not this energy of relaxation not to lose, during weak loads one could imagine a very important restriction: this would allow the engine to burn the diesel fuel well (less air to be heated during the combustion, therefore T ° higher, making less unburned, and as less nitrogen admitted, less NOX)

note that the ERG valve works a little in this direction

bolt

0 x

-

divad_nitram

- I learn econologic

- posts: 13

- Registration: 12/02/06, 19:19

- Location: Montpellier (France)

Hello,

We advanced on our engine:

- Found a bubbler already made of stainless steel, the exhaust gases warm the bottom, a tube plunges into the liquid and warmed, I do not know what it is worth but we only have an arc station to weld and mastered not too much the thing .... we will see what it gives like that otherwise we will make one.

- Mount the rod in the tube by putting a pin that passes through the tube and the core is suspended by a hook.

- manufactured the small whistle pipe and mounted in the intake pipe, sealing with a dubious paste

It remains to find the appropriate piping to connect all this, is the cooling hose is sufficient (t °)? If it is absolutely necessary to do it in copper, will welding with a basic butane stove be sufficient?

It going....

A+

David

We advanced on our engine:

- Found a bubbler already made of stainless steel, the exhaust gases warm the bottom, a tube plunges into the liquid and warmed, I do not know what it is worth but we only have an arc station to weld and mastered not too much the thing .... we will see what it gives like that otherwise we will make one.

- Mount the rod in the tube by putting a pin that passes through the tube and the core is suspended by a hook.

- manufactured the small whistle pipe and mounted in the intake pipe, sealing with a dubious paste

It remains to find the appropriate piping to connect all this, is the cooling hose is sufficient (t °)? If it is absolutely necessary to do it in copper, will welding with a basic butane stove be sufficient?

It going....

A+

David

0 x

Bonjour David,

Being your direct neighbor (10km), I offer you a little help if you wish. Ex. Soldering sticks, sheets (falls) possible bends even a few welds! yes a little because very little time available! and I'm doing my editing.

and I'm doing my editing.

I realize, according to my availability of turbulators, graciously for the friends but if you are interested no problem!

Otherwise no brazing on this type of assembly, because bad resistance to strong variations in temperature and vibrations (except for money) A + lusitano

Being your direct neighbor (10km), I offer you a little help if you wish. Ex. Soldering sticks, sheets (falls) possible bends even a few welds! yes a little because very little time available!

I realize, according to my availability of turbulators, graciously for the friends but if you are interested no problem!

Otherwise no brazing on this type of assembly, because bad resistance to strong variations in temperature and vibrations (except for money) A + lusitano

0 x

-

divad_nitram

- I learn econologic

- posts: 13

- Registration: 12/02/06, 19:19

- Location: Montpellier (France)

Hi,

We went back to it:

The engine always starts, here's what we did:

- Replacement of copper pipes with car cooling hoses (until then it fits)

- we have done the sealing of the quilting in the body of the carb with a paste called I do not know how

- Put a heat shield because by dint of cramer Fred in the fed up

- put a thermocouple that melted after 6s

- Ensured the sealing of the threads with a special thermal paste

And we started the tests without charge:

- One has the aspiration through the whole system until the diver of the bubbler

- When you put water and gasoline (40-60), the engine runs using the gasoline vapors that come out of the bubbler when the fuel supply is cut off, but the reactor does not work. after us because:

- no depollution

- no significant temperature gradient (IR thermometer)

- When we put an alcohol-water mixture 50-50, there the engine does not manage to turn with this mixture through the reactor, when we disassemble the whole we observe a temperature gradient inverted with respect to the direction of the gases d 'exhaust.

The temperature measurements were performed using a non-contact infrared thermometer, which measures on a pellet of 3 cm in diameter, so not obvious to have an accurate measurement.

The temperature measured outside the reactor is between 300 ° C on the exhaust pipe and 240 ° C on the outlet tee of the reactor.

Here is what it looks like disassembled, the part where is connected the valve is the one that is positioned furthest from the exhaust pipe.

We will now try the following things for it to work:

- Put a load using an 2 kW generator and an electric heater, maybe the engine does not suck up enough empty fuel?

- let it heat up longer (10min until then), we found liquid alcohol water mixture at the exit of the reactor after he had stalled

- play on the engine speed to see if the system changes anything, for now the accelerator is at full speed all the time

- Set up 2 thermocouples and a data acquisition unit on these two probes and a flow meter, with that we will know more about the proper functioning of the endothermic reactor.

I continue to keep you informed for the future ...

A+

David

We went back to it:

The engine always starts, here's what we did:

- Replacement of copper pipes with car cooling hoses (until then it fits)

- we have done the sealing of the quilting in the body of the carb with a paste called I do not know how

- Put a heat shield because by dint of cramer Fred in the fed up

- put a thermocouple that melted after 6s

- Ensured the sealing of the threads with a special thermal paste

And we started the tests without charge:

- One has the aspiration through the whole system until the diver of the bubbler

- When you put water and gasoline (40-60), the engine runs using the gasoline vapors that come out of the bubbler when the fuel supply is cut off, but the reactor does not work. after us because:

- no depollution

- no significant temperature gradient (IR thermometer)

- When we put an alcohol-water mixture 50-50, there the engine does not manage to turn with this mixture through the reactor, when we disassemble the whole we observe a temperature gradient inverted with respect to the direction of the gases d 'exhaust.

The temperature measurements were performed using a non-contact infrared thermometer, which measures on a pellet of 3 cm in diameter, so not obvious to have an accurate measurement.

The temperature measured outside the reactor is between 300 ° C on the exhaust pipe and 240 ° C on the outlet tee of the reactor.

Here is what it looks like disassembled, the part where is connected the valve is the one that is positioned furthest from the exhaust pipe.

We will now try the following things for it to work:

- Put a load using an 2 kW generator and an electric heater, maybe the engine does not suck up enough empty fuel?

- let it heat up longer (10min until then), we found liquid alcohol water mixture at the exit of the reactor after he had stalled

- play on the engine speed to see if the system changes anything, for now the accelerator is at full speed all the time

- Set up 2 thermocouples and a data acquisition unit on these two probes and a flow meter, with that we will know more about the proper functioning of the endothermic reactor.

I continue to keep you informed for the future ...

A+

David

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 41 Replies

- 53882 views

-

Last message by Flytox

View the latest post

28/02/14, 18:43A subject posted in the forum : Water injection in engines: montages and experiments

-

- 4 Replies

- 15969 views

-

Last message by Flytox

View the latest post

19/11/13, 22:03A subject posted in the forum : Water injection in engines: montages and experiments

-

- 8 Replies

- 11280 views

-

Last message by Flytox

View the latest post

20/05/10, 22:46A subject posted in the forum : Water injection in engines: montages and experiments

-

- 25 Replies

- 23808 views

-

Last message by Other

View the latest post

19/03/10, 03:11A subject posted in the forum : Water injection in engines: montages and experiments

-

- 0 Replies

- 7855 views

-

Last message by F4AGL

View the latest post

07/12/09, 20:42A subject posted in the forum : Water injection in engines: montages and experiments

Back to "Water injection in the engines: the assembly and experimentation"

Who is online ?

Users browsing this forum : No registered users and 196 guests