Bonsoir

Good first day of test frankly disappointing. I more or less adjust my drip rate at 1litre / H but my problem is with the air filter. The water from the drip passes from a pipe of 6mm arrives at a T or is connected the small gasoline filter and continuous at the beginning GVI. when removing the air filter surprise there is water in it? I do not understand the air is logically aspire there should not be any water?

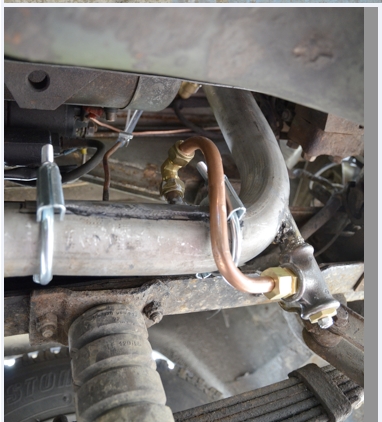

Mercedes truck 508D in water doping

It takes shape!

Your copper pipe between the GVI and the reactor is a little exposed to cooling, you can isolate it a little bit.

For the filter that fills with the fleet, it is a sign that does not aspire much in your reactor. You might need to try to mount the filter a few cm higher (10-15 cm?). If it does not matter, you should try another place to get the air, further down.

You can also try to put a venturi on the intake manifold to boost the suction.

With what do you seal the GVI with the sheet on the pot?

0 x

Reason is the madness of the strongest. The reason for the less strong it is madness.

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

Hey Hello

I am not going to put an insulating plumbing foam;

And for the filter you're right I realized it just after i actually go up the air filter, the suction looks good and my conso pr moment of water is a little more than 1 liter al hour.

The seal between the GV and the pot sheet is the wood stove rope with refractory glue tightness is good I made it in case I have changes to do.

Unfortunately finally, fortunately I am no longer sedentary with the beautiful day I left on the road so no workshop for DIY and therefore the venturi will wait unless it is absolutely necessary to put one.

I just made 150 terminals on national 90km / h max but very often between 70 and 80 conso 11L5 instead of 12 / 13 but my measurements are not very accurate ... level polution I never really smoke black but there is still a strong smell of imbrulé I find ...

I guess as long as it pollutes there will not really be any conso drops? in general if more pollution means that the system works?

Thank you for your advice I take the road will try to make more accurate conso statements

@ + xav [/ List]

[/ List]

I am not going to put an insulating plumbing foam;

And for the filter you're right I realized it just after i actually go up the air filter, the suction looks good and my conso pr moment of water is a little more than 1 liter al hour.

The seal between the GV and the pot sheet is the wood stove rope with refractory glue tightness is good I made it in case I have changes to do.

Unfortunately finally, fortunately I am no longer sedentary with the beautiful day I left on the road so no workshop for DIY and therefore the venturi will wait unless it is absolutely necessary to put one.

I just made 150 terminals on national 90km / h max but very often between 70 and 80 conso 11L5 instead of 12 / 13 but my measurements are not very accurate ... level polution I never really smoke black but there is still a strong smell of imbrulé I find ...

I guess as long as it pollutes there will not really be any conso drops? in general if more pollution means that the system works?

Thank you for your advice I take the road will try to make more accurate conso statements

@ + xav

0 x

timeisat wrote:I am not going to put an insulating plumbing foam;

Watch out, how much does the "plumbing insulating foam" hold in temperature? The stuff like black foam "rubber" that does not exceed 150 ° and you are against the pot which goes up to more than 500 ° when you accelerate a little hard. Don't get on fire

I just made 150 terminals on national 90km / h max but very often between 70 and 80 conso 11L5 instead of 12 / 13 but my measurements are not very accurate ... level polution I never really smoke black but there is still a strong smell of imbrulé I find ...

The conso, it must be done on a good distance to average (1 full?) Otherwise the vagaries of circulation, different routes and weather etc .... introduce too much error.

For the smell chai not if it's really representative.

At low speeds a Gillier Pantone or Pantone hardly works but it is there that we can feel the smell. It would sniff at 90Km / h but it is less convenient ....

I guess as long as it pollutes there will not really be any conso drops? in general if more pollution means that the system works?

The pollution which decreases a little is easy to obtain very quickly, for the significant improvement in pollution and consumption .... it is necessary to scratch a moment .....

To optimize your editing, it should be limited / cut in one way or another, the drip when the vehicle is idling or very low speed. Otherwise the fleet eventually accumulates in the GVI or bottom of the reactor, and when you accelerate, there is too much water to heat, there will be a delay in the production of steam (desynchronization) and it disrupts the operation and can even make problems / failures.

Do you have a way of monitoring steam production? Steam outlet temperature for example? This is essential to visualize what we are doing, the influence of the settings ... The engine does not "say anything" when it is sent "steam" at 65 or 250 ° but it certainly does not work the same on all this temperature range. This allows you to see if all of a sudden the temperature collapses in town for example (flooding of the reactor), or never rises (insufficient heating, flow too low etc ...), or yoyote between 2 values more or less distant in a few seconds or minutes depending on the road or your speed (instability) etc ... This allows you to learn

/ understand the operation of the bagpipe to get an idea of how to modify

0 x

Reason is the madness of the strongest. The reason for the less strong it is madness.

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

alaniesse wrote:Hello Timeisat, Hello Flytox

Congratulations for this advanced Timeisat, Bravo Flytox for the right advice

Timeisat can you indicate where you ordered the stainless steel tubes? Thank you

Hello

Well I have it is buy on Bordeaux in a box that is specialize in stainless steel if you type in google stainless steel + your city you will find easily after pr info we buy tube you stem to 5 truck so 1 stem and 2 tube meter for 65 € all not sold by the meter but by 3 or 6 metered but looking for good we find voila

@ + xav

0 x

ok thanks Xav

What do you use for your sealing washers, copper, brass, aluminum between black iron and brass / copper connections?

For the tip of the stainless steel rod that was threaded, you do not prefer a black steel reduction rather than brass?

you sucked a stainless steel threaded rod or a smooth rod that you turned in at the end?

what did you put in paste attached, holtz 1000 degrees, silicone 350 degrees, other?

Thank you

Lau

What do you use for your sealing washers, copper, brass, aluminum between black iron and brass / copper connections?

For the tip of the stainless steel rod that was threaded, you do not prefer a black steel reduction rather than brass?

you sucked a stainless steel threaded rod or a smooth rod that you turned in at the end?

what did you put in paste attached, holtz 1000 degrees, silicone 350 degrees, other?

Thank you

Lau

0 x

alaniesse wrote:ok thanks Xav

What do you use for your sealing washers, copper, brass, aluminum between black iron and brass / copper connections?

For the tip of the stainless steel rod that was threaded, you do not prefer a black steel reduction rather than brass?

you sucked a stainless steel threaded rod or a smooth rod that you turned in at the end?

what did you put in paste attached, holtz 1000 degrees, silicone 350 degrees, other?

Thank you

Lau

Hi, the reactor T is in "black" steel and the elbow in stainless steel then all the pipes are in copper and the brass fittings in olive history minimize welds as much as possible and, if necessary, disassemble and modify. The reactor core is 316L that I turned at a corner turner and the 304 L threaded rod from Roy Merlin threaded rod that I then abraded except the end to put a stop nut and this are welds that I made on the core that I then filed down to 1mm to keep an annular space in the tube of 1mm. For the paste c, refractory glue resistant to 500 ° C with a wood stove cord as described above in this page. I am a novice but I used André's plans https://www.econologie.com/plan-et-conse ... -3727.html and adapt to my sauce according to the config of my pot voila

0 x

Hi Xav

your welds, did you do them with silver, or bronze?

Depending on the photos, the colors change.

I see that you have used tube 2 mm, for the tube around the bar.

saw that the stainless steel is less good in exchange, I put only 1 mm thick, to have the maximum heat. I know that's not usual.

To see if your reactor works, you can try it with an electric fogger and demineralised water, 1 one head is enough to test.

gvi: beefy, time required for focusing, normal water

Brumisteur: ultra efficient, fragile, can only work with demineralized water.

your welds, did you do them with silver, or bronze?

Depending on the photos, the colors change.

I see that you have used tube 2 mm, for the tube around the bar.

saw that the stainless steel is less good in exchange, I put only 1 mm thick, to have the maximum heat. I know that's not usual.

To see if your reactor works, you can try it with an electric fogger and demineralised water, 1 one head is enough to test.

gvi: beefy, time required for focusing, normal water

Brumisteur: ultra efficient, fragile, can only work with demineralized water.

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 1 Replies

- 12253 views

-

Last message by Flytox

View the latest post

08/07/08, 19:58A subject posted in the forum : Water injection in engines: montages and experiments

-

- 30 Replies

- 39175 views

-

Last message by Mido66

View the latest post

12/05/09, 11:49A subject posted in the forum : Water injection in engines: montages and experiments

-

- 25 Replies

- 19571 views

-

Last message by bolt

View the latest post

28/02/06, 23:51A subject posted in the forum : Water injection in engines: montages and experiments

-

- 171 Replies

- 170514 views

-

Last message by phil 14

View the latest post

26/03/07, 23:23A subject posted in the forum : Water injection in engines: montages and experiments

Back to "Water injection in the engines: the assembly and experimentation"

Who is online ?

Users browsing this forum : No registered users and 89 guests