Pantone modification for Renault Laguna 2.0l petrol

Another little bit of advancement:

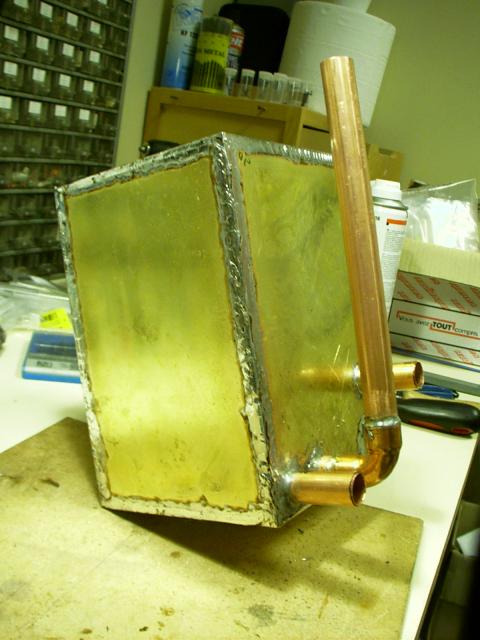

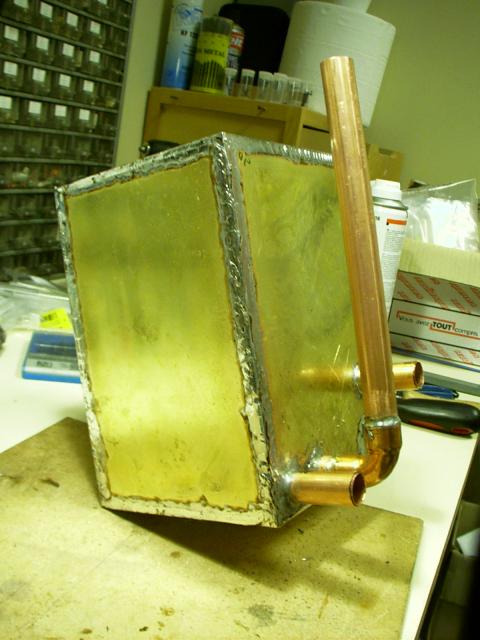

System for emptying the bubbler, soldered in tin on the bottom plate:

I bought copper tube 16/18, to make the heating coil, the air inlet, and the outlet to the reactor.

I'm going to have to find a way to bend the tube without crushing it. They had the spring which makes it possible to do that, but 10 € the trick to use it only once, it annoys me a little ...

Following the next issue ...

System for emptying the bubbler, soldered in tin on the bottom plate:

I bought copper tube 16/18, to make the heating coil, the air inlet, and the outlet to the reactor.

I'm going to have to find a way to bend the tube without crushing it. They had the spring which makes it possible to do that, but 10 € the trick to use it only once, it annoys me a little ...

Following the next issue ...

0 x

So the bubbler is almost finished. Almost because I still have to make the transparent cover with its seal, and drill one of the sides to weld the air outlet to the reactor.

Here are some photos :

I opted for a multitude of small holes to try to make a lot of small bubbles, and less swirl in the bubbler.

Following the next issue ...

Here are some photos :

I opted for a multitude of small holes to try to make a lot of small bubbles, and less swirl in the bubbler.

Following the next issue ...

0 x

- do you drive

- I understand econologic

- posts: 102

- Registration: 20/08/05, 16:53

- Location: Belgium

- x 3

Hi nlc,

it's great work.

Do not forget that the water level above your tube with holes must be 1 to 2 cm max. otherwise there may not be many bubbles.

Good work,

it's great work.

Do not forget that the water level above your tube with holes must be 1 to 2 cm max. otherwise there may not be many bubbles.

Good work,

0 x

Patrick Guidi

www.pfgtechnologie.be

www.pfgtechnologie.be

Thank you!

I put in the water last night, and it seems that the bubbler is waterproof, it's already a good thing.

For the water level above the hole tube, there may be a little more if I want the coil to completely bathe in the water. If it does not bubble enough, I would put less water, the coil will not be completely submerged, but as there will be less water to heat ...

But I think that even if there is 5 cm of water it will bubble anyway, because where I am going to plug in at the intake it sucks strongly.

I put in the water last night, and it seems that the bubbler is waterproof, it's already a good thing.

For the water level above the hole tube, there may be a little more if I want the coil to completely bathe in the water. If it does not bubble enough, I would put less water, the coil will not be completely submerged, but as there will be less water to heat ...

But I think that even if there is 5 cm of water it will bubble anyway, because where I am going to plug in at the intake it sucks strongly.

0 x

Hello Guidi

The water level in the bubbler can reach a maximum of 200mm in height C, this is how the threshold for triggering bubbling begins around 2000rpm. (at low speed it is preferable not to bubble too cold)

To get this bubbling you need a good depression (case of a diesel or a valve or a restriction, the best is a venturi in the intake), on the test on my venturi in the intake, 100kmh it siphone a colone more than 700mm

obviously it is less in front of the reactor.

the other advantage of having a certain level in the bubbler it places the inlet of the reactor in depression it vaporizes more water

Guidi are you short on time or haven't had good results?

Give us your feedback on your editing, at the beginning of the tests it is always a little disappointing, but it takes some simple adjustments and it replaces.

On my side the cool is over it's the big cold -20 last night, I need to review the system because it does not operate anymore

at 12 and over, I'm thinking of a bubbler from another more compact principle. If it works I will tell you about it, I suppose that close to zero you should also feel a little difference.

In very cold weather in city use, cars consume 2 to 3 times more ...

Andre

The water level in the bubbler can reach a maximum of 200mm in height C, this is how the threshold for triggering bubbling begins around 2000rpm. (at low speed it is preferable not to bubble too cold)

To get this bubbling you need a good depression (case of a diesel or a valve or a restriction, the best is a venturi in the intake), on the test on my venturi in the intake, 100kmh it siphone a colone more than 700mm

obviously it is less in front of the reactor.

the other advantage of having a certain level in the bubbler it places the inlet of the reactor in depression it vaporizes more water

Guidi are you short on time or haven't had good results?

Give us your feedback on your editing, at the beginning of the tests it is always a little disappointing, but it takes some simple adjustments and it replaces.

On my side the cool is over it's the big cold -20 last night, I need to review the system because it does not operate anymore

at 12 and over, I'm thinking of a bubbler from another more compact principle. If it works I will tell you about it, I suppose that close to zero you should also feel a little difference.

In very cold weather in city use, cars consume 2 to 3 times more ...

Andre

0 x

André says: either a valve or a restriction, the best is a venturi in the intake), on the test on my venturi in the intake, 100kmh it siphone a water column of more than 700mm

a venturi is the easiest to install right? I was told that an adjustable spring-loaded valve at the inlet of the air filter was better but a little more boring to do.

I would like some clarification on this question.

0 x

The number of molecules in a drop of water is equal to the number of drop that contains the Black Sea!

-

- Similar topics

- Replies

- views

- Last message

-

- 1 Replies

- 6103 views

-

Last message by I Citro

View the latest post

29/11/07, 23:29A subject posted in the forum : Water injection in engines: montages and experiments

Back to "Water injection in the engines: the assembly and experimentation"

Who is online ?

Users browsing this forum : No registered users and 210 guests