Hello

Welcome to the water doping testers

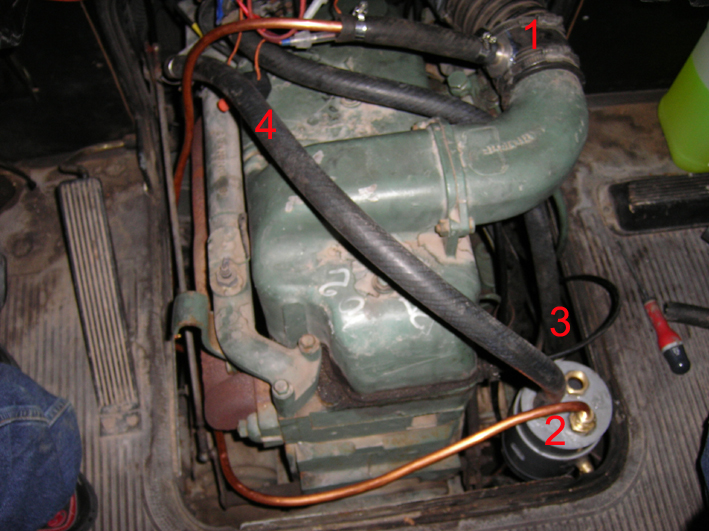

A beautiful new stainless steel pipe for the ocasion (the welder found hard the stainless steel welding flange)

what is the motivation, to reduce the copper output duct bubbler? (easier to bend?) Good desicion, I also decreased the diameter on me montages for other reasons

The bubbler is of original construction, to watch if it is resistant to the pressure of the hot LDR (it would be a nuisance to miss ldr to make an antifreeze leak even if these engines have a cast iron head do not peter the seal breech)

Why did you add a transparent hose in the inlet manifold inlet? to see the steam circulating in the duct

in sustained operation and load it becomes hot in this conduit

the bubbler duct (and given the little available place it has become long) it would be preferable to insulate it with a commercially available foam cover for water pipe that avoids internal condensation.

For depression if you want more it takes a venturi in the admission and avoid having a level too high in the bubbler

For the consumption test the yield is lower when you walk to oil 100% oil I have more than a liter of differrence

The engine is installed in a 5 vans manual gearbox

which consumes more than a car

these engines are around 2400rpm that are the most economical

On a 300D turbo engine 3 liters 125hp automatic gearbox that consumed before panton of 9,5 liters to 100km sometimes 10litres to 120kmh ..

the problem in the tests before doping with water was 90km which was at its best now it is at 110kmh which is at its best ..

In this reactor the central stem is tubular or they have put an internal baffle ..

Good tests ..

Andre