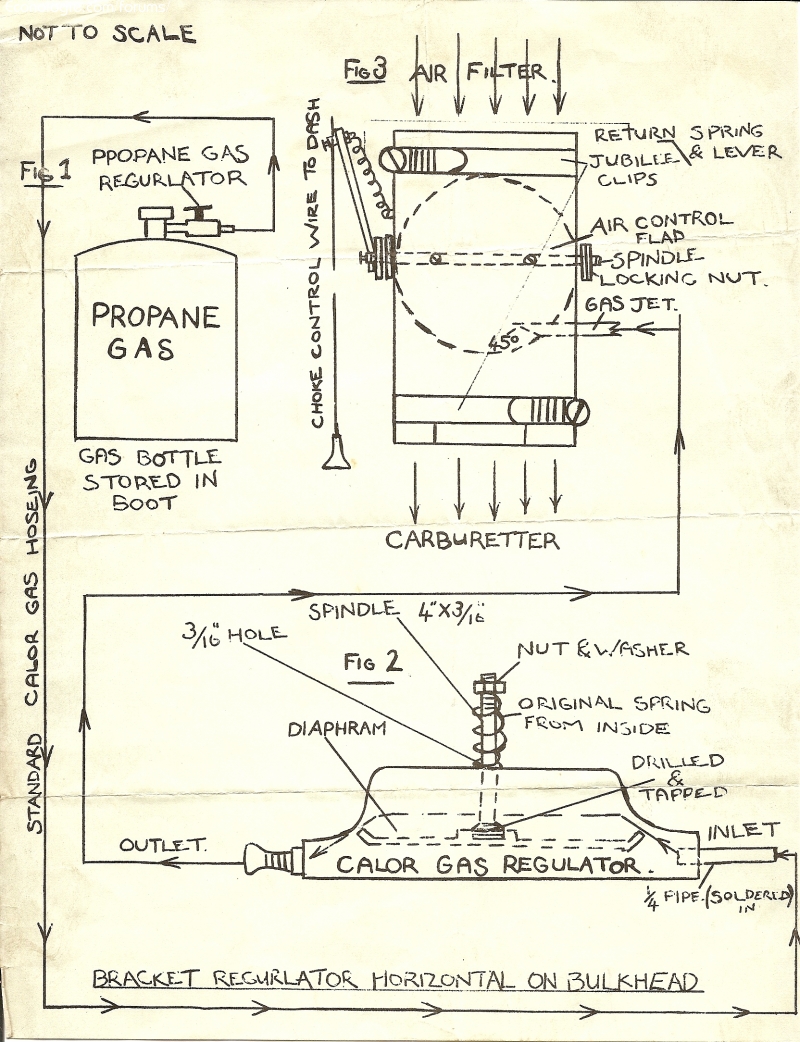

effectively leaving it at idle, it then suffices to inject the (bio) gas, through the air circuit.

after the air filter I think it does not risk anything, anyway a gas bottle has its own safety regulators etc ... otherwise it would risk a lot for gas stoves ... the small injector can not heat in this place , it is not in contact with the engine t ° C;

examples of assembly carried out, and others (biogas compressor, ...):

http://www.gaspoweruk.co.uk/history/har ... tions.html

where we see the accelerator:

the injector:

it is on it is not an installation at 3000 €, without state aid!

but it is an "old" simple assembly:

http://journeytoforever.org/biofuel_lib ... _bate.html

like last night I saw a C3 CNG: it was a GRDF vehicle ...

make a "homemade" digester (which manages CO2 well):

http://biorealis.com/digester/construction.html

http://biorealis.com/digester/operation.html